A couple of winters ago while working on "Mowboto: Robot Lawn Mower" in my unheated outdoor workshop, I realized I needed an indoor project with some heat. Phase 1 (Radio Controlled) was completed. Phase 2 was suppose to be a micro controller enhanced version to replace the RC communication adding GPS and sensor detection. I know..I've heard it before...A normal person would have simply bought a couple of heaters. But everybody in this forum knows all too well...

If (iOldFartEngineer * iCNerdYears <= Int64.MaxValue){

new Thread(new ThreadStart(DIYwithNetduinoPlus2)).Start();

Always fascinated with CNC's, I rationalized it was the perfect Proof-In-Concept platform for designing my Phase 2 hardware and software. Of course buying a ready made CNC kit was out of the acceptable realm of reason.

I spent a couple of weeks bouncing between Inkscape & SketchUp until I had a design which fit perfectly on top of my 3'x5' steel desk in the basement workshop. Power tools in hand, plenty of glue and plywood from Home Depot, and McMaster-Carr website, another CNC is born.

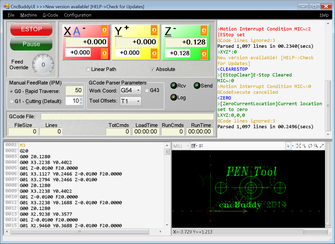

The NetduinoPlus2 running my "cncBuddyCAM" is attached to a wireless router. I make extensive use of multi-threading, binary command protocol, and SDCard as a local cache to minimize network traffic while cutting.

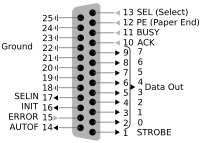

During cutting, continuous throttled location messages are sent back to the PC "cncBuddyUI" keeping the 3DViewer current. GCode cut jobs are stored and processed from the SDCard provided excellent caching performance. cncBuddyCAM is driving a 4 axis drive controller setup for 6400 steps/inch. 2 steppers are software slaved for XAxis, 1 for YAxis, and 1 for ZAxis. It's in 1/16� step/full step mode (microstepping), while the motors are 200 steps per rev. 3200 steps per rev. 2 turns per inch screws. NetduinoPlus2 drives this beast at 80-100ipm without breaking a sweat.

You can download the software and give it a spin....

https://osstekz.github.io/cncBuddy/

I've even added functionality for using a Nintendo game controller for use as an analog jogging device.

Enjoy!

Find content

Find content Not Telling

Not Telling