- Netduino Forums

- → Magpie's Content

Magpie's Content

There have been 156 items by Magpie (Search limited from 20-April 23)

#25331 Anyone is interested on a high-end acquisition shield?

Posted by

Magpie

on 10 March 2012 - 01:40 PM

in

General Discussion

Posted by

Magpie

on 10 March 2012 - 01:40 PM

in

General Discussion

#25332 CT Sensor help please!

Posted by

Magpie

on 10 March 2012 - 02:01 PM

in

General Discussion

Posted by

Magpie

on 10 March 2012 - 02:01 PM

in

General Discussion

#25448 Delay or getting stuck at deployment "Preparing to deploy assemblies to t...

Posted by

Magpie

on 13 March 2012 - 11:09 AM

in

Visual Studio

Posted by

Magpie

on 13 March 2012 - 11:09 AM

in

Visual Studio

#25488 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 14 March 2012 - 03:49 AM

in

Project Showcase

Posted by

Magpie

on 14 March 2012 - 03:49 AM

in

Project Showcase

#25535 How much current can you draw from the 5v pin?

Posted by

Magpie

on 15 March 2012 - 06:00 AM

in

Netduino Plus 2 (and Netduino Plus 1)

Posted by

Magpie

on 15 March 2012 - 06:00 AM

in

Netduino Plus 2 (and Netduino Plus 1)

#25598 Multithreaded Webserver and DataLogger

Posted by

Magpie

on 16 March 2012 - 08:11 AM

in

Project Showcase

Posted by

Magpie

on 16 March 2012 - 08:11 AM

in

Project Showcase

#25599 Detecting Sensor Type

Posted by

Magpie

on 16 March 2012 - 08:32 AM

in

Netduino Plus 2 (and Netduino Plus 1)

Posted by

Magpie

on 16 March 2012 - 08:32 AM

in

Netduino Plus 2 (and Netduino Plus 1)

#25605 Steff Shield

Posted by

Magpie

on 16 March 2012 - 10:39 AM

in

Project Showcase

Posted by

Magpie

on 16 March 2012 - 10:39 AM

in

Project Showcase

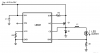

The only trouble is digikey doesn't like my credit card. So I might have to use the A8499 which is similar but not as good. Attached is a schematic of the shield without the actual led drivers.

I haven't decided on a chip for the Led Driver, I have been looking at hysteretic control, which is turned on and off by PWM at speeds in the kilohertz.

Hysteretic control is basically measuring the current through the inductor and turning on when it is lower than the low threshold and turning off when the current is higher than the high threshold. It's very efficient because it minimises the switching rate.

This seemed perfect until I realised that this would still be noisy in the top end of the hearing range. I really want the converter to operate in continuous mode to reduce noise. Wheres the LM3401 goes into and out of continuous mode at 20khz.

I have plenty of options but no obviously good ones.

- adjust the thresholds rather than the enable.

- use a different chip with a different control method.

- go back to a home brew style circuit.

#25606 Minimum AnalogInput Read value

Posted by

Magpie

on 16 March 2012 - 11:13 AM

in

Netduino Plus 2 (and Netduino Plus 1)

Posted by

Magpie

on 16 March 2012 - 11:13 AM

in

Netduino Plus 2 (and Netduino Plus 1)

#25643 Minimum AnalogInput Read value

Posted by

Magpie

on 17 March 2012 - 01:28 AM

in

Netduino Plus 2 (and Netduino Plus 1)

Posted by

Magpie

on 17 March 2012 - 01:28 AM

in

Netduino Plus 2 (and Netduino Plus 1)

#25649 Minimum AnalogInput Read value

Posted by

Magpie

on 17 March 2012 - 10:04 AM

in

Netduino Plus 2 (and Netduino Plus 1)

Posted by

Magpie

on 17 March 2012 - 10:04 AM

in

Netduino Plus 2 (and Netduino Plus 1)

#25673 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 18 March 2012 - 07:21 AM

in

Project Showcase

Posted by

Magpie

on 18 March 2012 - 07:21 AM

in

Project Showcase

#25763 Sharing code between projects

Posted by

Magpie

on 20 March 2012 - 10:49 AM

in

Visual Studio

Posted by

Magpie

on 20 March 2012 - 10:49 AM

in

Visual Studio

So some of your source code is identical, in both types of projects, so you only want to maintain one copy of it. Is that what you want?

You definitely can't share the compiled code, but I don't think there is any reason that you can't share the source code, if you can get it to compile in both types of projects. You might have to use a lot of ifdefs or whatever C# has for conditional compilation.

I think you would be better off having two solutions and cutting and pasting any similar code.

That way you can have two instances of visual studio and can debug both at the same time.

#25882 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 23 March 2012 - 02:25 AM

in

Project Showcase

Posted by

Magpie

on 23 March 2012 - 02:25 AM

in

Project Showcase

#25924 [UK] Electrical Supply help

Posted by

Magpie

on 24 March 2012 - 11:38 AM

in

General Discussion

Posted by

Magpie

on 24 March 2012 - 11:38 AM

in

General Discussion

#25926 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 24 March 2012 - 11:43 AM

in

Project Showcase

Posted by

Magpie

on 24 March 2012 - 11:43 AM

in

Project Showcase

#25928 [UK] Electrical Supply help

Posted by

Magpie

on 24 March 2012 - 12:21 PM

in

General Discussion

Posted by

Magpie

on 24 March 2012 - 12:21 PM

in

General Discussion

#25983 Steff Shield

Posted by

Magpie

on 26 March 2012 - 11:59 AM

in

Project Showcase

Posted by

Magpie

on 26 March 2012 - 11:59 AM

in

Project Showcase

I would be happy to send you something for trial. Sorry it's taken so long to reply.

It seems I can't easily avoid the hysteresis style dimming, but I am just a bit worried about em noise.

Still there are things you can do about it. I will look into that later once it is built.

Basically I want to use a buck topology, this is a step down only converter and as such is slightly more efficient than a step up or a step up/down converter. Have a look in Wikipedia if you need more background.

The only slight difference with the led driver circuit from a normal buck converter is that we pulse modulate to set our desired current, where most converters pwm to set the voltage as long as the current is not above some limit.

We will choose the non synchronous version because it is a lot simpler and only has slightly higher inefficiencies.

To make a Led driver Stupidly efficient we have to work out where our losses will be.

From Wikipedia. Sorry if I don't elaborate every point.

Conduction losses that depend on load:

Switching losses:

- Resistance when the transistor or MOSFET switch is conducting. (we will choose a fet with this as low as possible. we need to drive fet at high enough joltage to minimize this.)

- Diode forward voltage drop. (we will choose a diode with Vf as low as possible.)

- Inductor winding resistance. (we will choose an inductor with R as low as possible. This is where most drivers skimp.)

- Capacitor equivalent series resistance. (we will choose capacitors with R as low as possible.)

- Voltage-Ampere overlap loss. (we will minimize switching through our hysteris method and make sure that we control the fets gate fast. Also Totem pole should not go into heavy saturation.)

- Frequencyswitch*CV2 loss. (choose fet with small gate capacitance)

- Reverse latence loss. ( I think this is about the diode and it being a fast recovery type.)

- Losses due driving MOSFET gate and controller consumption. ( make sure that the driving transistors are biased properly, otherwise minimise as best you can.)

- Transistor leakage current losses, and controller standby consumption. (shouldn't apply to fets)

If you want to know a very good app. note on driving fets see this one by Laszlo Balogh .

I have decided on the NCL30160 from On Semi and because it seems the most efficient, even though the driver chip has an internal fet. The internal fet should simplify things.

The NCL30160 has a very low Rds on( resistance in ohms between drain and source when the fet is turned on.) , compared to its peers, so it was the clear winner.

In the data sheet is has a circuit diagram, I have lifted it straight into SteffShield.

We still have to select component values though, I will make a prototype and see what I can get out of it.

#26068 How to draw 220V motor

Posted by

Magpie

on 29 March 2012 - 12:43 AM

in

General Discussion

Posted by

Magpie

on 29 March 2012 - 12:43 AM

in

General Discussion

#26123 AnalogInput Repeatability

Posted by

Magpie

on 30 March 2012 - 05:43 AM

in

Netduino 2 (and Netduino 1)

Posted by

Magpie

on 30 March 2012 - 05:43 AM

in

Netduino 2 (and Netduino 1)

#26288 analog to digital conversion

Posted by

Magpie

on 03 April 2012 - 12:12 AM

in

General Discussion

Posted by

Magpie

on 03 April 2012 - 12:12 AM

in

General Discussion

#26316 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 03 April 2012 - 12:44 PM

in

Project Showcase

Posted by

Magpie

on 03 April 2012 - 12:44 PM

in

Project Showcase

#26318 Steff Shield

Posted by

Magpie

on 03 April 2012 - 01:16 PM

in

Project Showcase

Posted by

Magpie

on 03 April 2012 - 01:16 PM

in

Project Showcase

I also got the ICs.

I am hoping that most of my efficiency will come from

- using the hysteresis mode to limit the amount of switching,

- the high quality inductors

- and the low rds on of the led drivers.

I am fairly sure that if the cable run is short to the leds from the driver the noise wont be an issue.It really seems to be coming along! Have you had any more thoughts in terms of the drivers themselves in terms of noise constraints?

The some applications may have longer runs, I am hoping by using twisted pair cables this wont be an issue. Cat 5/6 I think would work well.

I plan to drive the Led Driver with it's maximum pwm input frequency which is 20khz..

Whatever noise is present will be in harmonics of those 20khz. This may give electro-magnetic noise in the 20khz to 200khz region. I am not sure what equipment will be effected by this, if anybody knows please say so.

The other option was to use a non hysteretic mode and keep the buck converter in continuous mode all the time.

This would have less noise, possibly less efficiency and would take larger inductance. I think switching at around 200-500 khz would give near the best efficiency. I haven't found a great solution here, but I am sure there is one. Probably two external fets and a half bridge driver to give a Synchronous buck converter.

I will post an image of the pcb soon.

#26319 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 03 April 2012 - 01:25 PM

in

Project Showcase

Posted by

Magpie

on 03 April 2012 - 01:25 PM

in

Project Showcase

#26339 USB Audio Device - FINALLY WORKS!!

Posted by

Magpie

on 03 April 2012 - 10:46 PM

in

Project Showcase

Posted by

Magpie

on 03 April 2012 - 10:46 PM

in

Project Showcase

- Netduino Forums

- → Magpie's Content

- Privacy Policy