- Netduino Forums

- → Magpie's Content

Magpie's Content

There have been 156 items by Magpie (Search limited from 06-July 24)

#38474 Powerful Aquarium Lighting

Posted by

Magpie

on 03 November 2012 - 11:47 PM

in

General Discussion

Posted by

Magpie

on 03 November 2012 - 11:47 PM

in

General Discussion

#38545 Powerful Aquarium Lighting

Posted by

Magpie

on 05 November 2012 - 09:56 AM

in

General Discussion

Posted by

Magpie

on 05 November 2012 - 09:56 AM

in

General Discussion

#36036 Powerful Aquarium Lighting

Posted by

Magpie

on 26 September 2012 - 11:11 PM

in

General Discussion

Posted by

Magpie

on 26 September 2012 - 11:11 PM

in

General Discussion

#35937 Powerful Aquarium Lighting

Posted by

Magpie

on 25 September 2012 - 02:16 AM

in

General Discussion

Posted by

Magpie

on 25 September 2012 - 02:16 AM

in

General Discussion

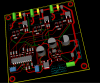

I have done, I found it quicker now that I know what I am trying to acheive. If you had a lot of obvious connections then I think that the autoroute can do those fairly easily.I've been playing around trying to do the track widths, do you place all the tracks yourself

The ratsnest will dissappear as each node is fully connected. If you are using vias for higher current paths then you can use multiple.and if so how do you make sure you are connecting up correctly/ deal with vias?

Default for thin, 8mm for thick and say 3mm if it is carrying some current. But reduce these widths just for segments where it is necessary.What widths do you think I should be aiming for, for my thin, medium and thick traces and what clearances would I need?

Do your placement first obviously.

I haven't looked have you changed anything since last time I looked?In terms of my layout, which is similar(ish) to yours can you see anything that will/may cause me a glaring issue?

Sorry Andrew, I was actually Sailing all weekend, it was fantastic.

Did you sort out how to change track widths, I know it is very cumbersome.

You probably found this out already but

assign a track to a track type in the digital rules.

When you lay it out it will take the track width of the track type.

If you want to temporarily make some tracks a different width such as for the ground plane, Where the Kelvin connections carry a tiny current and the power ground has high current you can just change the track width for the track type(eg. High Current) while you lay that track. Then set it back to normal.

Also sometime you want to run the track thin into the pins but run it fat for most of the length.

First run it thin, then change the track thickness for the track type and right click and adjust the track thickness on the segments that you want thicker.

for the thicknesses

Connections into the processor only need to be thin. Power tracks make thick. Tracks on the ouput stage make thick as you can but thin them down as they feed into the component legs. It basically comes down to the current through the track. 8mm wouldn't be amiss joining the inductor to the Fet and the diode, if you can fit that much.

I quite liked my posistioning of the components, to minimise track lengths for the high current tracks. But maybe you want the connectors to be organised differently.

As for the Kelvin connections run them as pairs or threes lik it did. The only place the ground of the kelvin connection touches ground is at the sense resistor.

the point is we want to measure the voltage of the ground at the sense resistor compared to ground at the micro, but using only the minimum current we can to do it. (Conceptually tricky). Also we want the minimum induced noise so we run the differential inputs right next to each other, for as long as posible.

Hope this helps

#35299 Powerful Aquarium Lighting

Posted by

Magpie

on 15 September 2012 - 01:12 PM

in

General Discussion

Posted by

Magpie

on 15 September 2012 - 01:12 PM

in

General Discussion

#38645 Powerful Aquarium Lighting

Posted by

Magpie

on 06 November 2012 - 10:23 PM

in

General Discussion

Posted by

Magpie

on 06 November 2012 - 10:23 PM

in

General Discussion

I think you should build something soon, but I have a different idea for you for control.

the netduino can talk SPI and the attiny can talk SPI. so you could drop the tlc5940s completely.

Just have the netduino set the dimming level direct to the attiny via SPI. The only trouble with this is you would loose one channel of PWM, giving you two outputs per attiny.

Although if you can handle a small blink while the communication is done you could have 3 channels.

Also I have never written any SPI code in AVR so you would be on your own there.

L1 will be ok, it just needs to fit mechanically and I think it will fit but it will be tight.

If it doesn't fit you can easily make it fit by soldering L1 just off centre or filing a small notch into the ic socket.

You understand you need to use a socket dont you? I am not sure if I made this clear.

I tried editing the pad offset, but every time I pressed OK, and went back in to the settings, it had gone back to zero?

Right click on the footprint and Open the footprint in the module editor. Set the working library to say 'Andrew' and put all your mods as you do them in here. Create a new part from what is in the editor and save it into your footprint library. At this point you can save it as you make changes. Once it is done then delete the old footprints and place the new footprints into your pcb. The tracks may be no longer connected, so reconnect them using your knowledge of grids and snap to.

One day when I get something looking good made I will post about my latest version, hopefully soon.

Yes I think before the final board is built you could optimise, but it is so hard to get the perfect design from scratch. It is iterative and I think 2 iterations will be your minimum.Let me know how you get on with your new boards, out of interest I know you have dropped a channel, but how small do you think I could realistically drop these boards to? I don't know if I definitely will, especially if these boards work, but I may lay it all out on one big board eventually with the TLC board built in and the power distribution for the 30 channels will be much more elegant and a lot of the connectors could be dropped. I could essentially get away with a GO! bus connector and a power plug, but this really is dreaming ahead!

If you get this first board made in small quanties, turn it on then I think you will find unexpected things, good and bad, especially in regards to the lighting aspect of it.

#39781 Powerful Aquarium Lighting

Posted by

Magpie

on 21 November 2012 - 01:07 AM

in

General Discussion

Posted by

Magpie

on 21 November 2012 - 01:07 AM

in

General Discussion

#42694 Powerful Aquarium Lighting

Posted by

Magpie

on 04 January 2013 - 11:41 AM

in

General Discussion

Posted by

Magpie

on 04 January 2013 - 11:41 AM

in

General Discussion

Hi Andy We are just having the hottest day in Hobart for around 40 years, 41.6C. I am sitting with a wet cloth on my head trying to cool down. Did you buy the house? If you did I hope you have a dedicated Aquarium room. the voltage across RL should be 5volts (+/- say 5%) at low currents ( high load resistance) and up till the current limiter kicks in. The Attiny is happy with 3.3v up to 5.5 volts and 5.04 volts sounds just right. You need two current settings very low and normal. Use say 30mA to test for shorts and then say 100mA to see if the led works and then you can probably discard the current limiter for that board.

Cant get some of the links for digikey. the 0.1uf are ok.

goto go sorry back in a few days.

#40199 Powerful Aquarium Lighting

Posted by

Magpie

on 25 November 2012 - 10:45 PM

in

General Discussion

Posted by

Magpie

on 25 November 2012 - 10:45 PM

in

General Discussion

Lets face it was your diligence not mine. I normally just buy the first thing.Thanks those caps got me down to about £70!

I wouldn't change the BJTS they are good quality and not so expensive and have been used in Steff2.

I think Atten 858D , (Dave does a video too, #167) do a budget heat gun (dont get ZHIAOXIN 858D and YiHUA 858D, and check earthing before using), but If you want to save money a small wedge shaped soldering tip would probably be good enough for the whole job..

Copper braid.Can you think of anything else that will be useful?

I have had my own mcpcbs manufactured. mcpcb I think it was $30 for 600 peices + $170 for tooling postage and TT payment. <sigh>

You can mount them on FR4 but need thermal vias. Each led doesn't need a huge amount of Al and it depends on a few factors but you can definitely get away with 50mm x 50mm for each XTE or XPG led. Probably even less. Heat sink at the back mean you can place them closer together, but they make a lot of light.

I am using Steff2 in my workshop and it gives enough light, maybe a little more than a single fluoro. 21 leds @ maybe 300mA. I don't think heat will be a big problem.

my calc was 3 x 500mA x 3.15 volts = 4.725W

+ attiny and gate drivers 5v x 100ma = .5W

+ inefficiency = .5W

Total power for 3 channels on one board = 5.725W @ 5v = 1.1 amps.

? each led has its own channel, in this case there is no series or parrallel. In the 12v 24v, and 36v designs you have the led strings in series. You cant really parrallel the leds without individual power resistors to share the currents equally, this is wasteful so not considered.I'll go to really plain terms now, so in terms of voltage drop in series this would be 3.15v per LED so you would need say 12v, but we get away with 5v as the channels run in parallel right?

Current i.e. the 1 or 1.5 amps we will supply can be larger than the required 700ma plus any other losses, as the circuit will only take what it needs right? Would this increase if say we needed 5 LEDs in a row to say 4A or does current not drop like voltages does in series hence it would still be 1 - 1.5A?

So here's where I get confused, where do Watts come in to the equation?

For example will my 5v 1A wall wart be able to power all 10 of my boards and I guess I would need to distribute the power in a parallel design between the 10 boards right?

If you run 10 boards or 30 channels of 1 led then you will need 1 x 11 amp 5 volt supply. Or you can use 5 x 2.2 amp supplies or 10 x 1.1amp supplies. Dont parrallel the supplies just join the negatives as common. Keep the the positives of the supplies separate to each other.

Try not to overload a supply, you can probably use standard 1amp wall warts but maybe turn the power down a smidge. you can do this in the attiny firmware so that the Netduino firmware cannot cause failure. Check the warmth of the Wall wart while at full load. You don't really need to use wall warts there are other more efficient supplies.

Also I would put a smoke detector in your lab especially while still in development.

#39942 Powerful Aquarium Lighting

Posted by

Magpie

on 22 November 2012 - 12:10 PM

in

General Discussion

Posted by

Magpie

on 22 November 2012 - 12:10 PM

in

General Discussion

Try these.

445-1369-1-ND

on the caps you can go down to 16v which still leaves a comfortable safety factor. None of the caps need accurate tolerances or temp coefficients.

the fets should be at least 20v.

same with the bjts.

I probably waste a bit of my money but then again we aren't just about to buy a house.

#39923 Powerful Aquarium Lighting

Posted by

Magpie

on 22 November 2012 - 01:49 AM

in

General Discussion

Posted by

Magpie

on 22 November 2012 - 01:49 AM

in

General Discussion

#32886 Powerful Aquarium Lighting

Posted by

Magpie

on 30 July 2012 - 01:07 AM

in

General Discussion

Posted by

Magpie

on 30 July 2012 - 01:07 AM

in

General Discussion

Seen plenty of similar errors myself.

the not connected, you just need to zoom in an check it is connected, I think the colour changes in the middle.

If you don't want to connect to a pin, you put a "NO Connect" symbol on blue cross. It's just a message to the DRC.

Also if you label a node, and want to use this node somewhere else you might have mistakenly give a different name.

There are also power markers, that you place like components, these may have the same name as labels but are different.

Eg. you have to label a node as GND if you want to use it in different places, but you also need to attach a power marker to it which will be called Gnd.

You have to say where the power is coming from, you can either ignore it or edit a connectors pin, if it is coming off board.ErrType(3): Pin connected to some others pins but no pin to drive it

@ (1.6750 ",1.2000 "): Pin 15 (power_in) of component IC1 is not driven (Net 10).

Ignoring it is fine if you are sure what is providing power. I did manage to get my design pass DRC but it was a bit of frigging around.

My mount holes are stupidly big on my board. I think my power vias could be bigger.

#32873 Powerful Aquarium Lighting

Posted by

Magpie

on 29 July 2012 - 01:50 PM

in

General Discussion

Posted by

Magpie

on 29 July 2012 - 01:50 PM

in

General Discussion

#30556 Powerful Aquarium Lighting

Posted by

Magpie

on 11 June 2012 - 11:14 PM

in

General Discussion

Posted by

Magpie

on 11 June 2012 - 11:14 PM

in

General Discussion

#30769 Powerful Aquarium Lighting

Posted by

Magpie

on 16 June 2012 - 12:30 PM

in

General Discussion

Posted by

Magpie

on 16 June 2012 - 12:30 PM

in

General Discussion

The details are on my domestic lights project . It is based on the Attiny but with some improvements.

I hope this helps.<br>

#29736 Powerful Aquarium Lighting

Posted by

Magpie

on 25 May 2012 - 01:50 AM

in

General Discussion

Posted by

Magpie

on 25 May 2012 - 01:50 AM

in

General Discussion

Finally I have my lights working.Hope your boards work out fine, you will have to let me know how they go.

I haven't used or really looked at the Go architecture yet, but I think it may suit your project.

#29451 Powerful Aquarium Lighting

Posted by

Magpie

on 21 May 2012 - 12:04 AM

in

General Discussion

Posted by

Magpie

on 21 May 2012 - 12:04 AM

in

General Discussion

The 5 volt output is not meant to be used by you so don't use it. It is used internally to power the logic of the chip.

It needs a decoupling capactior so if something suddenly turns on or off your logic still has close enough to 5 volts. ( I think it is 5v).

The thing about decoupling capacitors is that they don't need to be accurate, they just need to be big enough and fast enough, Surface mount ceramic is fast enough and 2.2u or 4.7u (which is what I used) is big enough.

In short 2.2uF is fine.

I think the 180k is only a ball park number, it is about the minimum off time. It doesn't really matter as long as it is fairly close to that number.Finally the 180k does the equation for this take in to account the RSense and if so do I need to calculate this myself for my RSense of 0.285? Is there a suggested power rating for these?

do the power calculations for the 180k resistor. if your maximum ciruit voltage is 12V then your maximum power in the 180k = 12 * 12 / 180000 = 5uW.

If you do more electronics you will start to see that a high resistance equates to low power dissipation.

So if I was using say a 5v supply for 1 LED and a 12v supply for 3 LEDs is there anything else that needs changing in the circuit?

Minimum input voltage to the NCL30160 = 6.3 volts.

Just run them all off 12 volts. You wont loose much.

Are you spinning your own board or using vero board?

I have bought 100 leds and designed my own mcpcb, they should arrive this week, I hope the mcpcbs don't have any errors.

#27860 Powerful Aquarium Lighting

Posted by

Magpie

on 22 April 2012 - 12:55 AM

in

General Discussion

Posted by

Magpie

on 22 April 2012 - 12:55 AM

in

General Discussion

Better to bring it down to some lowish dc voltage and use a led driver for each channel from there.

I was talking on another forum about my troubles with the NCL30160 and a couple of things were suggested.

1. run at a lower voltage ie. 12 or 24 even though the chip is rated at 40V

2. use a transient suppression diode across the vin. one that suppresses at a voltage just above the vin you want to use.

3. bread boarding high frequency power circuits is fraught with difficulty, and could have been the cause of some of the problems

Also I said before you may get away without the inductors but I think you need them unless your nominal led string voltage is near your maximum dc voltage.

eg. 3 leds at 3 volts = 9 volts running from 12v probably doesn't need the inductor.

but 1 led at 3 volts = 3 volts running from 12v probably does need the inductor because the instantaneous voltage across the led may cause a large instantaneous current that is too much for the led.

#30795 Powerful Aquarium Lighting

Posted by

Magpie

on 17 June 2012 - 01:44 AM

in

General Discussion

Posted by

Magpie

on 17 June 2012 - 01:44 AM

in

General Discussion

#31592 Powerful Aquarium Lighting

Posted by

Magpie

on 04 July 2012 - 11:11 PM

in

General Discussion

Posted by

Magpie

on 04 July 2012 - 11:11 PM

in

General Discussion

#32871 Powerful Aquarium Lighting

Posted by

Magpie

on 29 July 2012 - 12:39 PM

in

General Discussion

Posted by

Magpie

on 29 July 2012 - 12:39 PM

in

General Discussion

#32860 Powerful Aquarium Lighting

Posted by

Magpie

on 29 July 2012 - 12:09 AM

in

General Discussion

Posted by

Magpie

on 29 July 2012 - 12:09 AM

in

General Discussion

#31648 Powerful Aquarium Lighting

Posted by

Magpie

on 06 July 2012 - 10:30 AM

in

General Discussion

Posted by

Magpie

on 06 July 2012 - 10:30 AM

in

General Discussion

#31639 Powerful Aquarium Lighting

Posted by

Magpie

on 05 July 2012 - 11:00 PM

in

General Discussion

Posted by

Magpie

on 05 July 2012 - 11:00 PM

in

General Discussion

I know I am jumping in a little late here, but I just looked at the picture with the inductors. Aren't the ones on the left actually 33mH instead of 33uH?

I looked at this link coilcraft series

I must admit I don't know.

that's right.The bit in the bottom right corner is the black regulator right?

ps. I changed the logo, it will come out on the silkscreen.

I almost mounted the torroid footprints upside down, that would've been a disaster.

I just sent the gerbers off to seeed studio last night.

If you want I can send you some, I will test them first though.

#26758 Powerful Aquarium Lighting

Posted by

Magpie

on 09 April 2012 - 12:03 AM

in

General Discussion

Posted by

Magpie

on 09 April 2012 - 12:03 AM

in

General Discussion

- Netduino Forums

- → Magpie's Content

- Privacy Policy