REPRAP

#1

Posted 14 August 2010 - 10:48 AM

#2

Posted 14 August 2010 - 11:40 AM

#3

Posted 20 August 2010 - 02:36 PM

#4

Posted 22 August 2010 - 08:40 PM

I'm pretty new at this, but am wondering whether this board could be used to run the Mendel REPRAP machine? I mean, would it simply be a case of recompiling the Java code they provide, or would it need to be re-written from scratch?

I just found that there is a new RepRap G5 Mini Shield posted on http://www.thingiverse.com/thing:3863

It is specially designed to work with ARM boards, such like Netduino, FEZ domino, Maple Leaf and etc.

So I think that would take care of the hardware side.

On the software front I also found that the RepRap firmware is written so that it can be compiled by GNU GCC compiler:

http://reprap.org/wiki/General_FAQ

So I think instead of rewriting it in .NET Micro Framework, the easiest route would be to compile it natively and reflash the board. Don't get me wrong, I love the idea of RepRap.NET too, but .NET MF is not designed for real-time devices so I'm afraid it wouldn't work in this scenario. But I still hope someone else will shortly prove I was wrong.

#5

Posted 22 August 2010 - 08:47 PM

So I think instead of rewriting it in .NET Micro Framework, the easiest route would be to compile it natively and reflash the board. Don't get me wrong, I love the idea of RepRap.NET too, but .NET MF is not designed for real-time devices so I'm afraid it wouldn't work in this scenario. But I still hope someone else will shortly prove I was wrong.

Since .NET MF allows interop with native code, this is definitely possible using a mix of native C++ and managed C# code. Maybe managed C# code alone.

100% Native C++ code on the Netduino is definitely possible as well.

#6

Posted 22 August 2010 - 08:51 PM

Since .NET MF allows interop with native code, this is definitely possible using a mix of native C++ and managed C# code. Maybe managed C# code alone.

100% Native C++ code on the Netduino is definitely possible as well.

Chris,

It sounds very tempting to give it a try, and besides I wanted a MakerBot for some time alredy... but maybe I should finish some other projects first :-)

#7

Posted 23 August 2010 - 08:40 AM

#8

Posted 23 August 2010 - 03:42 PM

Also, as I mentioned earlier, I am really new at this - how would I begin to compile the Arduino firmware for the Netduino device? (I would guess I need to create a C# class and use the existing C++ Arduino code as a reference, but..?)

Two options:

1. Translate the C++ code to C#

2. Port the AVR C++ code to ARM C++ code, create a C# managed class wrapper around them, and compile it into the firmware.

Chris

#9

Posted 29 May 2012 - 09:04 PM

Two options:

1. Translate the C++ code to C#

2. Port the AVR C++ code to ARM C++ code, create a C# managed class wrapper around them, and compile it into the firmware.

Chris

So Chris, sorry for necroposting on this old thread, but I know you dint get to look around Maker Faire a lot this year so i am not sure if you saw that 3D printers were HOT. In looking around a bit since then I have found literally 10's if not 100's of design's or variation of a design out there. I really want to build one but have not want to depart from the Netduino universe. So what about we do our own version but with at least 1 key difference. for example (Simple) interchangeable heads. this way it would not only be a 3d printer but a CNC mill and maybe even a vinyl cutter.

The Netduino Go! with being able to control all those extra devices might be perfect. Or possibly this is a good use for adding in Ward's FPGA board to offload the actual stepper motor commands and just have the Netduino manage the overall process.

What does the community think?

http://jarrodsinclair.wordpress.com//

#10

Posted 29 May 2012 - 10:34 PM

#11

Posted 30 May 2012 - 08:11 AM

#12

Posted 30 May 2012 - 04:38 PM

So Chris, sorry for necroposting on this old thread, but I know you dint get to look around Maker Faire a lot this year so i am not sure if you saw that 3D printers were HOT. In looking around a bit since then I have found literally 10's if not 100's of design's or variation of a design out there. I really want to build one but have not want to depart from the Netduino universe. So what about we do our own version but with at least 1 key difference. for example (Simple) interchangeable heads. this way it would not only be a 3d printer but a CNC mill and maybe even a vinyl cutter.

The Netduino Go! with being able to control all those extra devices might be perfect. Or possibly this is a good use for adding in Ward's FPGA board to offload the actual stepper motor commands and just have the Netduino manage the overall process.

What does the community think?

I like it, i am actually in the middle of designing a 3axis controller GO module which makes use of some austria micro magnet rotary encoders for positioning and some ST dspin motor controllers, yet to decide on MCU for the module will either be a STM32F4 or a shiny new F0, i like the idea of a modular firmware where your implementation details (h-bridge with out microstepping to full on stepper controller) can largly be abstracted out although this is more an idle thought rather than something fully thought out, can already see several issues ho hum.

#13

Posted 30 May 2012 - 08:00 PM

One potential problem with a combined CNC mill and 3D printer would be rigidity. I've CNC converted a Proxxon MF70 mill and I'm finding it really useful. It's small but very solidly built and it needs to be if milling metal. Whenever I see any attempts at a combined printer/mill they really don't look up to the job. A dremel screwed to a piece of wood and running on some light rails isn't enough. Also the calibration that would be required when switching heads might be more trouble than it's worth. I'm not trying to put a downer on the idea, just raising some concerns. Personally I'd rather have two separate devices.

My current control setup is a PC running Mach3. This truly is a abomination of GUI design and I may swap it out for something Netduino based - especially now the Go has really opened up the possibility for native code on a module and hance the tight timings required for driving stepper motors smoothly. However, I'm now finding it useful to have a PC in the workshop. I can view toolpaths in Mach3 before milling, jog the mill position using gcode, and even fire up some design software for last minute tweaks.

The home CNC field (whether mill or printer) is definitely an interesting one.

Fred,

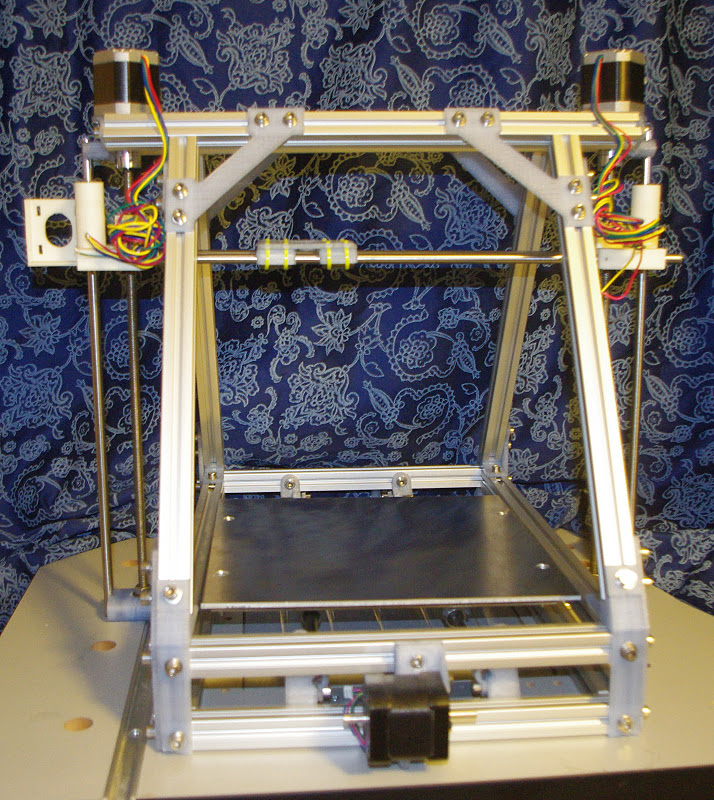

Good point on the Rigidness of the design. However, I was planning on using a modified MendalMax design which sports a box / triangle shaped frame made of 80/20 (of course the top brackets woudl need to be modified to support a CNC cutting tool). I have attached a picture below. For the swappable heads, my idea was to use something like a Slotted V, parallel rail plate, or a 4 bolt slot that will hold calibration between tool swaps (think of something like a Quick release for Cameras with hard stop plates). Then to mount the cnc cutter, using a dremal that is threaded onto the mounting bracket like an attachment. I know the tolerance would not be great (would be lucky to get .2mm) and the feed rate would be low, but it would be good enough for most home CNC / 3D printing use such as cutting and drilling your own PCB, printing boxes, plates and brackets, and other uses. Plus the cost would be very low

http://jarrodsinclair.wordpress.com//

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users